Choosing the Right Twist Tie Machine for Your Application

David Schiller, Engineering Group Manager

Twist tie machines are essential for businesses that need to secure bags, bundle products, or manage cables quickly and efficiently. Depending on the size of your operation and the products you’re handling, there are different types of twist tie machines to suit various needs.

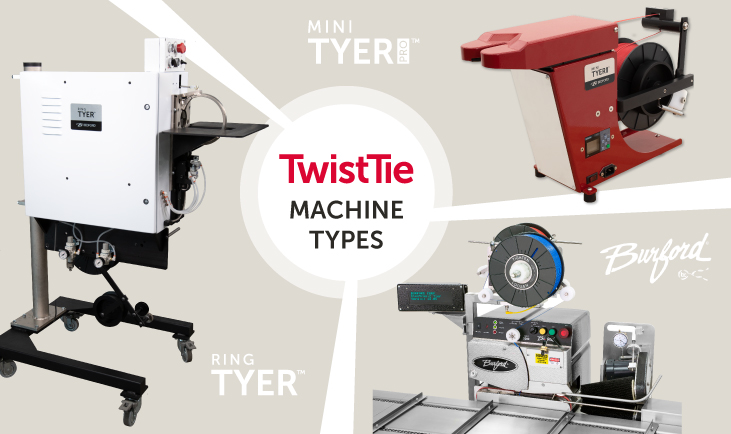

In this guide, we’ll explore three common tie machine types: Table-Top Tyer, Ring Tyer, and Automatic Tyers. Each has unique advantages depending on your application and desired speed.

1. Table-Top Tyer: Semi-Automatic and Ideal for Entry-Level Use

A Table-Top Tyer, such as Bedford’s Mini Tyer™ Pro, is the perfect twist tie machine for small to medium-sized businesses or those just starting. The user simply places the item inside the throat opening and lets the machine do the rest. This style of bag closing machine is usually designed to close between 40-60 bags per minute.

Key Benefits:

- Cost-Effective: Table-top tyers are affordable and great for businesses with lower packaging volumes.

- Versatile: Ideal for securing bags in many industries, including baking, industrial, food service, and candy industries.

- Compact: Its small footprint makes it perfect for tight spaces or businesses looking to maximize floor space.

- Compatible Tags: For added branding, Crafted™ Bag Tags rest within the throat opening and are applied seamlessly with the twist tie for an enhanced appearance.

- User-Friendly: Table-top tyers are easy to use, and with their low learning curve, employees can be up and running in no time.

2. Ring Tyer: Designed for Cables, Cords, and Bundles

If you’re bundling items like cords, cables, or hoses, a Ring Tyer (also known as a Bundle Tying Machine) is your best bet. This machine is designed specifically for products that don’t come in bags but need to be grouped together securely.

Key Benefits:

- Specialized for Bundles: Unlike general twist tie machines, the ring tyer excels at tying multiple items together with consistent tension, ensuring a clean and secure bundle.

- Adjustable Sizes: It can handle various bundle sizes, making it a versatile choice for manufacturers in industries like electronics, automotive, and warehousing.

- Efficient: Ring tyers save time and labor by automating the process of securing bundled items, increasing productivity on the assembly line.

- Compatible Tags: This machine can also apply a custom-printed ring tag to seamlessly add branding, product details, or warehousing information.

3. Automatic Tyers: High-Speed Automation for Larger Operations

For businesses requiring high-speed twist tying at scale, an Automatic Tyer is an essential investment. These machines, like the Burford Tyer, are designed to handle large volumes with minimal manual intervention, making them perfect for high-demand industries.

Key Benefits:

- Maximum Efficiency: Fully automatic twist tie machines can handle hundreds of ties per minute, making them ideal for large-scale manufacturing operations.

- Consistency: Every tie is applied with the same tension and precision, ensuring reliable packaging quality for every product.

- Reduced Labor Costs: By automating the twist tying process, you can reduce the need for manual labor, streamlining your operation and cutting costs in the long run.

These machines are common in industries that require rapid, continuous packaging, such as baked goods and large-scale manufacturing of packaged products.

Choosing the Right Twist Tie Machine

When selecting the right twist tie machine for your business, consider:

- Volume: How many ties will you need per day? If it’s a low to moderate amount, a table-top tyer might be enough. For higher volumes, a fully automatic tyer will maximize efficiency.

- Product Type: Are you tying bags, bundling cables, or securing loose products? Different machines specialize in different tasks, so match the machine to your specific application.

- Speed Requirements: If speed is crucial to your operation, fully automated machines offer the highest throughput, while semi-automatic table-top machines are better for smaller batches.

Conclusion

Twist tie machines come in various forms to fit different needs, from small businesses to large manufacturing facilities. Whether you’re packaging food, bundling cables, or running a high-speed production line, choosing the right twist tie machine can greatly enhance your efficiency and product quality. Consider your application, volume, and speed requirements to make the best decision for your business.

0 Comments