Bedford Double Wire Tin-Tie® vs. Bedford Peel & Stick®

Beth Radloff, Marketing Specialist

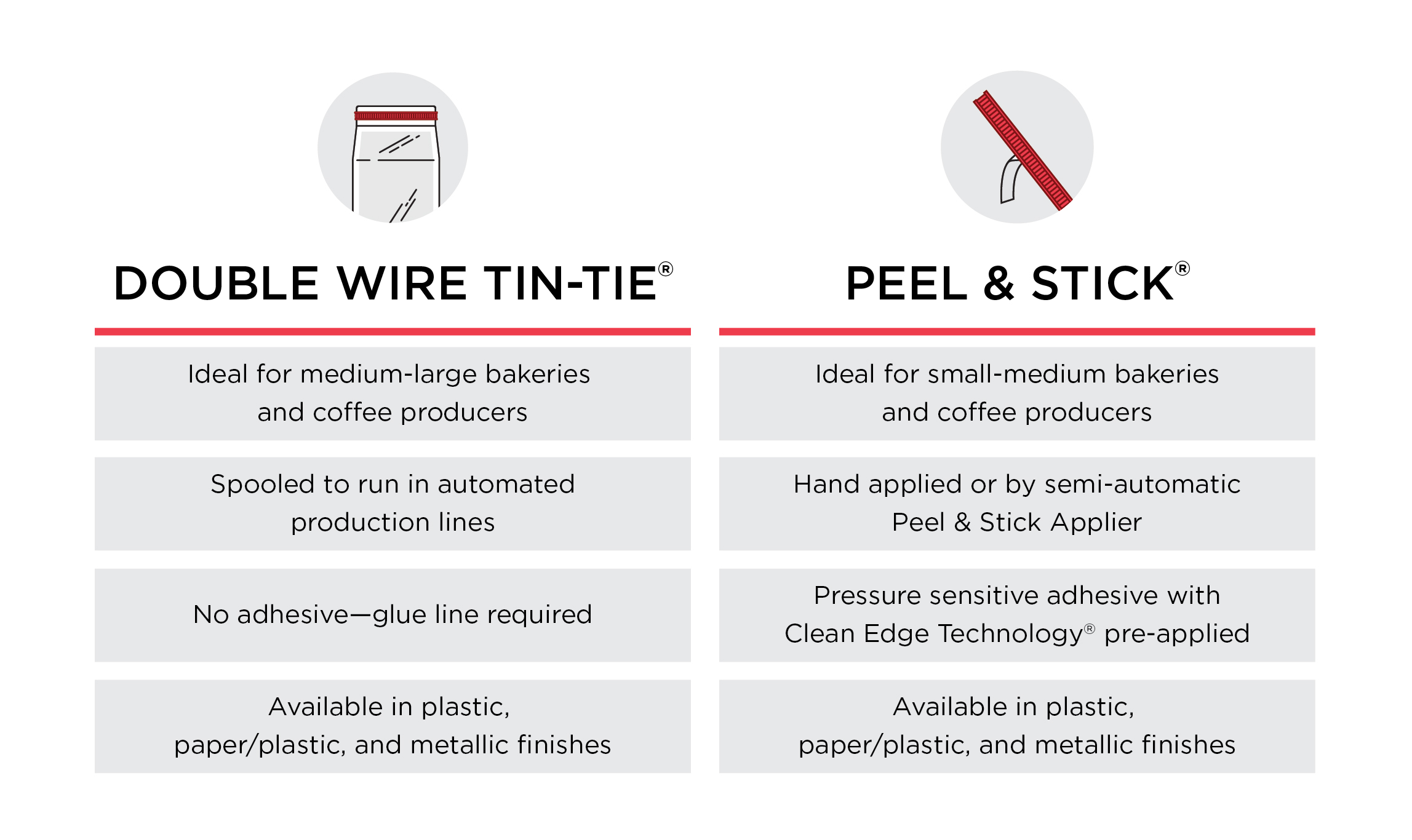

Side gusseted bags such as those used in the coffee, baked goods, and snack industry require a closure to increase the functionality of the packaging and maintain food freshness. Bedford offers two different options for flexible bag reclosability: Double Wire Tin-Tie® and Peel & Stick®.

Both are proven closures consumers have trusted for years and ensure your bag can be reclosed time and time again.

These two products may look the same but are very different. So, how do you know which one will work best for you? We can help with that decision! Here’s the breakdown.

Double Wire Tin-Tie®

If you are a medium/large scale manufacturer using automated packaging machines and have high volume output, Double Wire Tin-Tie may be the best option for you.

Available in plastic, plastic/paper, or metallic ties and a wide range of colors. Need a custom color or custom printing? Sure, no problem! It may be purchased in larger spools and since there is no adhesive, a glue/hot melt line would be required.

Peel & Stick®

Unlike Double Wire Tin-Ties, Peel & Stick is manufactured with pressure sensitive adhesive already applied to the tie – no hot melt adhesive required!

Peel & Stick ties are often used by small/medium-sized coffee producers or bakeries. Bedford’s exclusive Clean Edge Technology® adhesive leaves no sticky edges making it easier (and cleaner) to handle. Spooled tie is available for semi-automatic machines such as our Peel & Stick Applier, an affordable way to quickly (up to 30 bags/minute) and efficiently apply Peel & Stick to your bags.

Peel & Stick cuts are available for hand application. Choose from plastic, plastic/paper, or metallic ties and a wide range of colors. Custom colors and custom printing are also available.

Let’s review!

Choosing the best option

Still unsure which to choose? Let the Bedford team help select the best option for you. Contact us with any questions or sample requests you may have.

0 Comments